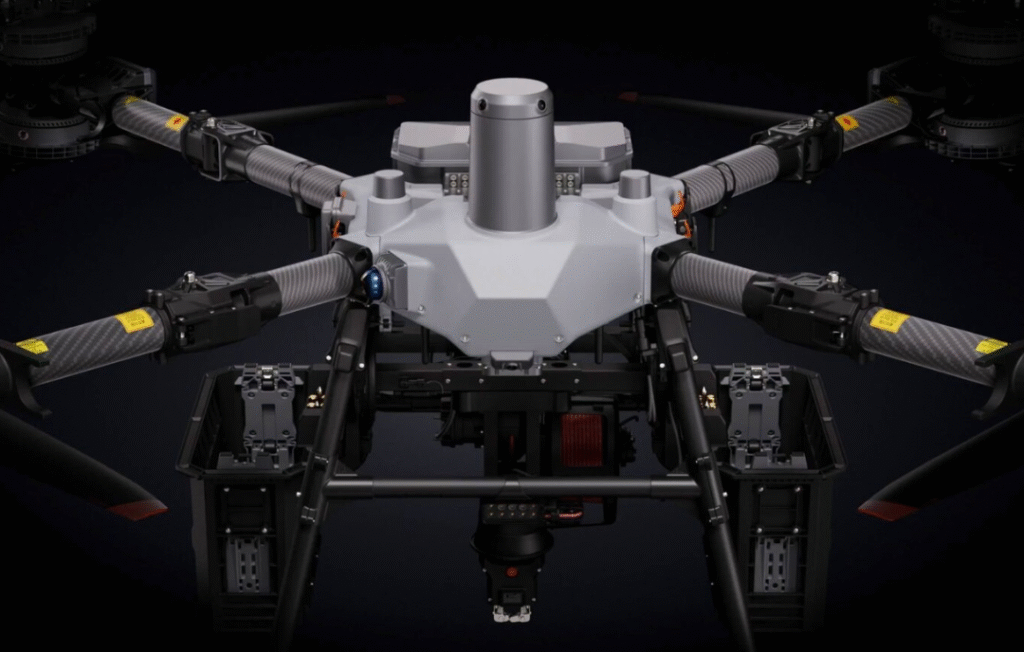

Heavy Payloads, Zero Compromise: DJI FlyCart 100 for Mission-Critical Tasks

The rapid evolution of aerial logistics is transforming how industries move heavy equipment, critical supplies, and mission-essential cargo. As infrastructure projects expand into remote terrains and time-sensitive deliveries become the norm, traditional ground transport often falls short. This is where heavy-lift drones are redefining operational efficiency, offering faster deployment, reduced manpower, and access to locations previously considered unreachable. At the forefront of this shift is the DJI FlyCart 100, a purpose-built heavy-lift cargo drone engineered to handle demanding industrial and enterprise-level logistics with precision and reliability.

Designed specifically for high-payload transport, the DJI FlyCart 100 represents a major leap beyond conventional delivery drones. Built to carry substantial loads over long distances, it combines advanced propulsion systems, intelligent flight control, and robust safety mechanisms to ensure stable operations even in challenging environments. Whether used in construction, mining, energy infrastructure, emergency response, or disaster relief, the FlyCart 100 enables organizations to transport tools, materials, and supplies efficiently while minimizing operational risk. Its modular payload options and automated flight capabilities make it adaptable to a wide range of professional use cases, setting a new benchmark for aerial cargo platforms.

More than just a logistics drone, the DJI FlyCart 100 is a strategic tool for industries looking to future-proof their operations. By reducing dependency on road access, lowering transportation costs, and improving delivery timelines, it unlocks new possibilities for aerial supply chains. As regulations around commercial drone operations continue to mature, platforms like the FlyCart 100 are poised to become integral to modern logistics ecosystems. In this article, we take a closer look at the DJI FlyCart 100’s capabilities, real-world applications, and why it is emerging as a game-changer in heavy-lift drone technology.

Key highlights for the DJI FlyCart 100

Heavy-lift aerial logistics is rapidly becoming a critical enabler for industries that operate in remote, time-sensitive, and infrastructure-poor environments. Purpose-built cargo drones now offer a safer, faster, and more efficient alternative to traditional ground transport. The DJI FlyCart 100 stands out in this space as a platform engineered specifically for industrial payload delivery, combining strength, intelligence, and operational reliability to meet enterprise-grade requirements.

Key Highlights

Purpose-Built Heavy-Lift Architecture

The DJI FlyCart 100 is designed from the ground up for carrying substantial payloads rather than adapting a camera drone for transport. Its reinforced airframe, high-torque propulsion system, and optimized weight distribution ensure stable flight while lifting heavy cargo across demanding operational scenarios.Advanced Safety and Redundancy Systems

Multiple layers of safety are integrated to support mission-critical operations. Redundant power systems, intelligent flight controls, and real-time monitoring help ensure controlled performance even in adverse conditions, reducing risk to cargo, personnel, and surrounding infrastructure during transport missions.Optimized for Industrial Logistics

The platform is well suited for construction, mining, utilities, and emergency response workflows. Its ability to bypass terrain constraints allows organizations to move tools, materials, and supplies directly to worksites, improving turnaround time and reducing dependency on road access or manual handling.Intelligent Flight and Operational Efficiency

Autonomous route planning, precision positioning, and consistent flight performance support repeatable logistics operations. These capabilities allow operators to scale drone-based delivery workflows while maintaining predictable outcomes, which is essential for enterprise and government deployments.Future-Ready Aerial Transport Platform

As regulations and industrial drone adoption continue to evolve, the DJI FlyCart 100 positions itself as a long-term logistics asset. Its modular design and enterprise focus make it adaptable to future payload systems, regulatory frameworks, and expanding use cases across multiple sectors.

Remote Controller & Transmission System

The remote controller and transmission system play a critical role in ensuring safe, precise, and reliable operation for heavy-lift drone missions. For enterprise logistics and industrial deployments, stable connectivity and responsive control are non-negotiable. The DJI FlyCart 100 is equipped with an advanced control ecosystem designed to support long-range cargo operations while maintaining high levels of situational awareness and command accuracy.

At the core of the system is a high-performance remote controller optimized for professional operators. It provides a clear, low-latency live feed, enabling pilots to monitor flight parameters, payload status, and surrounding airspace in real time. This level of visibility is essential when operating over complex terrain, construction zones, or disaster-affected areas. The DJI FlyCart 100 leverages an intelligent transmission architecture that maintains signal stability even in environments with electromagnetic interference or limited line-of-sight conditions.

The transmission system also supports extended operational range, allowing missions to be conducted efficiently without frequent repositioning of ground crews. Built-in failsafe mechanisms ensure that communication loss triggers predefined safety responses, protecting both the aircraft and its cargo. For enterprise users, this translates into predictable performance, reduced operational risk, and greater confidence during mission-critical deliveries. Overall, the remote controller and transmission system reinforce the DJI FlyCart 100 as a dependable aerial logistics platform capable of meeting demanding industrial requirements.

Batteries & Charging Performance

Reliable power management is fundamental to heavy-lift drone operations, where payload weight, flight duration, and mission safety are tightly interconnected. The battery and charging system of the DJI FlyCart 100 is engineered to support demanding industrial logistics missions, delivering consistent performance, operational efficiency, and reduced downtime in the field.

The platform utilizes high-capacity intelligent batteries designed to provide stable power output even under heavy payload conditions. Advanced battery management systems continuously monitor cell health, temperature, voltage, and charge cycles, ensuring optimal performance throughout each flight.

Safety Features

Safety is a critical priority in heavy-lift drone operations, where aircraft stability, payload security, and environmental awareness directly impact mission success. The DJI FlyCart 100 incorporates a comprehensive suite of safety features designed to support reliable operations in complex industrial and emergency environments.

Advanced sensing and obstacle awareness systems provide real-time detection of surrounding structures, terrain, and potential hazards. These systems assist operators in maintaining safe flight paths, particularly in confined or low-visibility areas such as construction sites, mountainous regions, or disaster zones. The DJI FlyCart 100 also integrates intelligent flight control algorithms that continuously adjust for wind resistance, payload shifts, and environmental changes, ensuring stable and controlled performance throughout the mission.

Redundancy is built into key systems to minimize risk during critical operations. Multiple layers of power, navigation, and communication backups help maintain aircraft control in the event of component failure. Automated failsafe functions, including return-to-home and controlled landing protocols, are triggered when abnormal conditions are detected. For enterprise and government users, these safeguards translate into reduced operational risk, enhanced compliance, and greater confidence during heavy-lift missions. Overall, the safety architecture positions the DJI FlyCart 100 as a trusted platform for professional-grade aerial logistics where reliability and risk mitigation are essential.

What's Included in the DJI FlyCart 100?

- Heavy-Lift Power: Supports payloads up to 80 kg (single battery) and 65 kg (dual battery).

- Maximum Takeoff Weight: 149.9 kg — engineered for industrial logistics and precision transport.

- Extended Range: Up to 26 km flight distance when unloaded, ideal for long-range operations.

- Fast Charging: 9-minute rapid charge keeps missions continuous with minimal downtime.

- Dual Cargo Modes: Switch between fixed cargo and winch delivery (30 m cable with load sensor).

- Rugged Reliability: Operates from –20 °C to 40 °C, resists 12 m/s winds, and rated IP55 for dust and rain.

- Advanced Safety Suite: Equipped with LiDAR, millimeter-wave radar, vision sensors, and an emergency parachute.

- Smart Control & Transmission: O4 system with up to 20 km video link plus optional 4G connectivity.

Accessories & Compatibility

To support diverse industrial missions, the DJI FlyCart 100 ecosystem is designed with a strong emphasis on modular accessories and broad system compatibility. This flexibility allows organizations to tailor the platform to specific operational requirements, whether for infrastructure development, emergency response, utilities, or remote logistics. By offering purpose-built accessories, the system ensures that performance, safety, and efficiency remain consistent across varied use cases.

One of the most critical accessory categories is the payload and cargo handling solutions. Depending on mission needs, operators can deploy cargo boxes or winch-based delivery systems, enabling secure transport and precise payload release. These accessories are engineered to integrate seamlessly with the aircraft’s flight control system, ensuring balanced weight distribution and stable flight performance even during dynamic lifting or lowering operations.

Power and charging accessories also play a vital role in sustained operations. High-capacity intelligent batteries are supported by dedicated charging systems that allow for efficient energy management and reduced downtime. This compatibility ensures that fleet operators can maintain predictable mission schedules while preserving battery health over long-term use. Additional power-related accessories help streamline logistics in field deployments and mobile command setups.

Warranty & After-Sales Support

Dronevex provides comprehensive warranty and after-sales support for the DJI FlyCart 100, ensuring enterprise customers receive dependable service throughout the product lifecycle. The platform is covered under DJI’s standard limited warranty, which includes the aircraft, remote controller, propulsion system, and core electronic components, while intelligent flight batteries are covered as per DJI’s specified usage and charge-cycle terms. This warranty applies to manufacturing and material defects under normal operational conditions, excluding damage caused by crashes, water exposure, unauthorized modifications, or improper use.

As an authorized DJI enterprise dealer, Dronevex coordinates all warranty claims and repairs through DJI’s official pan-India service network. This ensures access to genuine replacement parts, certified technicians, and manufacturer-approved repair processes. Customers benefit from structured service workflows, faster turnaround times, and transparent repair status updates, which are critical for organizations operating mission-critical logistics and industrial drone programs.

Who Should Buy the DJI FlyCart 100?

The DJI FlyCart 100 is specifically designed for organizations that require reliable, high-capacity aerial logistics solutions. Industries such as construction, mining, energy, and utilities often face the challenge of transporting heavy equipment, tools, and materials to remote or hard-to-access locations. For these users, the FlyCart 100 provides a safe, efficient, and time-saving alternative to traditional ground transport, reducing operational risk and accelerating project timelines.

Emergency response teams and disaster relief organizations also benefit greatly from the DJI FlyCart 100. In scenarios where road access is limited or impossible, this heavy-lift drone enables rapid delivery of critical supplies such as medical equipment, food, and rescue tools. Its modular payload system and precise flight control make it a dependable tool for time-sensitive missions, ensuring that teams can respond quickly and maintain operational continuity during emergencies or humanitarian efforts.

Finally, enterprises and government agencies investing in future-ready aerial logistics platforms will find the DJI FlyCart 100 highly advantageous. Its compatibility with industrial-grade accessories, intelligent flight systems, and professional-grade remote controller allows for scalable operations across multiple sites or applications. Organizations seeking to optimize supply chain efficiency, reduce manpower dependency, and explore innovative aerial delivery methods will find the FlyCart 100 a strategic investment that combines performance, reliability, and long-term operational value.

Conclusion

The DJI FlyCart 100 sets a new benchmark for heavy-lift drones, combining industrial-grade payload capacity, advanced flight control, and intelligent safety systems. Its design addresses the challenges of transporting equipment, materials, and critical supplies across remote or hard-to-reach areas, making it an indispensable tool for construction, energy, utilities, and emergency response operations. By integrating reliability, efficiency, and modular versatility, the FlyCart 100 transforms aerial logistics into a strategic asset for enterprises.

For organizations looking to future-proof their operations, the DJI FlyCart 100 offers more than just flight capabilities. With a robust ecosystem of batteries, cargo solutions, remote control systems, and comprehensive after-sales support from Dronevex, it ensures operational continuity and long-term value. Whether deployed for industrial projects, disaster relief, or innovative supply chain solutions, the FlyCart 100 delivers performance, safety, and adaptability, solidifying its position as a trusted heavy-lift drone for professional users.

FAQs

What is the payload capacity of the DJI FlyCart 100?

The DJI FlyCart 100 can carry heavy loads up to 100 kg, making it suitable for industrial transport, construction, and emergency logistics applications.

How long can the DJI FlyCart 100 fly on a single battery?

Flight time depends on the payload and mission profile. On moderate loads, it can operate for approximately 25–35 minutes per fully charged battery.

What type of batteries does the DJI FlyCart 100 use?

It uses high-capacity intelligent flight batteries with built-in monitoring for voltage, temperature, and charge cycles to ensure stable and safe power delivery.

Does the DJI FlyCart 100 come with a remote controller?

Yes, it includes a professional-grade enterprise remote controller that provides long-range, low-latency control and real-time telemetry.

Is the DJI FlyCart 100 suitable for emergency or disaster relief operations?

Absolutely. Its heavy-lift capacity and precise payload release make it ideal for transporting critical supplies to remote or disaster-affected areas.

Can the DJI FlyCart 100 fly in adverse weather conditions?

It is designed with advanced flight control and redundant systems to handle moderate wind and environmental conditions, but extreme weather (heavy rain, storms) should be avoided.

What safety features does the DJI FlyCart 100 have?

It includes obstacle sensing, redundant propulsion, automated failsafe protocols, and intelligent flight control to ensure safe and stable operation.

How is the DJI FlyCart 100 charged?

The drone comes with a dedicated charging system designed for fast, safe, and efficient battery replenishment. Multiple batteries can be cycled to minimize downtime.

What accessories are compatible with the DJI FlyCart 100?

Compatible accessories include cargo boxes, winch systems, additional batteries, propellers, remote controller modules, and safety sensor upgrades.

What kind of maintenance does the DJI FlyCart 100 require?

Routine checks of propellers, batteries, motors, and firmware updates are recommended. Regular inspections help maintain stability and payload reliability.

Is the DJI FlyCart 100 DGCA compliant in India?

Yes, when operated under the guidelines set by the Directorate General of Civil Aviation (DGCA) and with proper approvals for industrial operations.

Does the DJI FlyCart 100 support automated flight missions?

Yes, it supports autonomous route planning, precision positioning, and repeatable mission execution for industrial and logistical workflows.

How long is the warranty for the DJI FlyCart 100?

It is covered under DJI’s standard limited warranty, including aircraft and core components, with batteries covered per manufacturer specifications. Extended warranty options are available through Dronevex.

Can the DJI FlyCart 100 operate in remote locations without cellular networks?

Yes, the drone relies on GPS-based navigation and long-range remote transmission, so cellular connectivity is not required for normal operations.

Who should consider buying the DJI FlyCart 100?

It is ideal for enterprises, industrial operators, government agencies, emergency response teams, and organizations requiring heavy-lift aerial logistics solutions.