Increasing Survey Speed and Safety with DJI Dock Mining Automation

DJI Dock Mining Automation signals a new era in the evolution of mining operations, with DJI’s technology setting a benchmark for efficiency, safety, and data-driven decision-making. By integrating automated drone workflows and remote control capabilities through DJI Dock and FlightHub 2, mining enterprises can now deploy drones for routine aerial surveys, inspections, and data collection without on-site pilot intervention. These automated solutions mean recurring flights can be scheduled, monitored, and executed from remote operating centers, eliminating unnecessary travel time to hazardous environments and reducing human exposure to mine-site risks.

The transformative impact of DJI Dock Mining Automation is not only about operational convenience; it’s about regular, rapid, and reliable airspace coverage that drives smarter resource management and enables teams to react swiftly to changing site conditions. One high-impact example illustrated in field-tested case studies documents a dramatic reduction in photogrammetry survey times—from 1.2 hours down to just 30 minutes—using fully automated DJI Dock workflows.Furthermore, the implementation of DJI Dock Mining Automation brings substantial productivity gains across entire mining operations.

Sites equipped with a single DJI Dock system have demonstrated the ability to conduct up to 150-200 flights per month, totaling around 50 flight hours, while automated ground control point markings cut up to 94% of data processing time. These improvements go hand in hand with advanced edge computing, AI-powered modeling, and integration with photogrammetry platforms, allowing for on-demand event-triggered flights and intelligent data reporting. DJI Dock Mining Automation’s resilience is evident in harsh, real-world conditions, thriving in extreme temperatures, dust, and inclement weather. Through its advanced automation, regulatory-friendly frameworks, and intelligent cloud management, DJI Dock Mining Automation empowers mining institutions and operators to achieve new heights in operational excellence, safety, and cost-efficiency.

Key Efficiency Gains in Automated Mining Operations

The implementation of DJI Dock Mining Automation has revolutionized the way mining operations manage their workflows, significantly boosting productivity and safety. One of the most compelling advantages is the remarkable reduction in survey and data processing times. For example, a typical post-blast photogrammetry survey that traditionally took over an hour can now be completed in about 30 minutes, thanks to fully automated DJI Dock workflows. This efficiency gain allows mining companies to make faster data-driven decisions, reducing bottlenecks in critical operations such as blast planning, infrastructure monitoring, and stockpile inventory management.

Moreover, DJI Dock Mining Automation drastically increases operational capacity by enabling a higher flight frequency. With a single dock station, mining operations can achieve approximately 150-200 flights per month, totaling up to 50 flight hours. This high throughput translates into more frequent inspections and surveys, enabling continuous supervision of large, complex sites without the need for extensive on-site personnel or on-demand manual flights. The automation process also leads to substantial cost reductions by eliminating travel time, reducing staff requirements, and streamlining data processing workflows—saving up to 94% of the time previously spent on manual tasks.

The most significant advantage of DJI Dock Mining Automation is its proven reliability in extreme conditions. In Australian mining sites like Rio Tinto’s Gudai-Darri, drones operated persistently in temperatures reaching 50°C, amidst magnetic dust, and cyclone-prone weather, demonstrating robust resilience. This unwavering performance under harsh environmental factors highlights DJI’s focus on safety, reliability, and efficiency. The white paper and case studies reveal that by adopting DJI Dock mining automation, institutions can unlock new levels of operational excellence and safety, making these advanced workflows not just a technological upgrade but a vital strategic asset for future-ready mining enterprises.

Productivity Metrics and Flight Frequency

Mining operations today demand faster insights, safer workflows, and highly repeatable data collection—and that’s exactly where DJI Dock Mining Automation is transforming the landscape. By enabling fully automated, high-frequency drone flights, the system provides mines with continuous visibility, real-time updates, and reliable data that teams can act on instantly. Below are the key productivity metrics that highlight its impact:

Flight Frequency: With DJI Dock Mining Automation, mining operations achieve approximately 150-200 automated drone flights per month per dock system. This translates to around 50 flight hours monthly, allowing for consistent and frequent site inspections without manual pilot intervention.

Survey Efficiency: Automated workflows reduce the time required for post-blast photogrammetry surveys from 1.2 hours to just 30 minutes. This remarkable improvement accelerates data acquisition and processing, enabling faster decision-making and operational agility.

Data Processing Time: Integration with AI-driven automation cuts data processing duration by up to 94%, streamlining analysis and actionable reporting. These optimized workflows reduce labor intensity and improve overall productivity.

Operational Cost Savings: DJI Dock Mining Automation reduces travel requirements for drone pilots and minimizes on-site staffing needs. This reduction in logistical overhead significantly lowers operational costs while enhancing safety by keeping personnel remote from hazardous mine areas.

Environmental Resilience: The DJI Dock system reliably supports uninterrupted automated flights in extreme conditions such as high temperatures (up to 50°C), dust, and inclement weather, ensuring consistent productivity gains under harsh mining environments.

| Metric | Value with DJI Dock Mining Automation |

|---|---|

| Monthly Flight Count | 150-200 flights |

| Monthly Flight Time | Up to 50 hours |

| Post-Blast Survey Time | Reduced from 1.2 hours to 30 minutes |

| Data Processing Time Saved | Up to 94% reduction |

| Cost Savings | Significant reduction in pilot travel and staffing costs |

| Environmental Operability | Reliable function in extreme heat, dust storms, etc. |

Real-World Case Studies: Australian Mining Success Stories

The transformative power of DJI Dock Mining Automation is clearly demonstrated through real-world case studies from Australian mining operations that have adopted this revolutionary technology. One standout example comes from the Gudai-Darri iron ore mine in the Pilbara region, where DJI Dock Mining Automation enabled fully automated drone operations despite extreme conditions—intense heat soaring to 50°C, pervasive magnetic red dust, and cyclone-prone weather patterns. These drone flights, controlled remotely from thousands of kilometers away, provided critical and consistently accurate aerial survey data with high reliability, allowing mine operators to make timely, data-driven decisions while significantly enhancing worker safety by reducing the need for personnel presence in hazardous and high-risk operational zones across the site.

Another compelling success story involves Paddington Operations near Kalgoorlie in Western Australia’s goldfields. Here, DJI Dock Mining Automation facilitated aerial surveys of post-blast muckpiles, applying AI-driven modeling to improve grade control and reduce ore dilution. By accurately identifying higher-quality ore, the operation optimized processing efficiency and lowered costs per tonne. These case studies underscore how DJI Dock Mining Automation is not only enhancing operational productivity but also paving the way for safer, more sustainable mining practices. With regulatory frameworks in Australia supporting the rapid scaling of Beyond Visual Line of Sight (BVLOS) workflows, mining enterprises are empowered to fully leverage automated drone deployments, underlining DJI’s role as a key enabler of innovation and efficiency in one of the world’s most demanding industrial sectors.

DJI Dock Reliability in Harsh Mining Environments

DJI Dock Mining Automation is engineered for unparalleled reliability in the harsh and demanding environments of mining operations. Built with rugged, weatherproof housing and an IP56-rated enclosure, the DJI Dock withstands extreme conditions such as temperatures ranging from -30°C to 50°C, heavy dust, rain, and high humidity. This durability ensures consistent, uninterrupted drone deployments essential to maintaining frequent and precise aerial surveys, even in remote and challenging mining locations. The dock’s ability to function reliably in such environments provides mining enterprises with confidence in automating their drone workflows, minimizing downtime, and improving operational efficiency.

Extensive real-world case studies demonstrate the resilience of DJI Dock Mining Automation in extreme conditions. For instance, deployments at Australian mines such as Gudai-Darri have proven the dock’s capability to endure intense heat, pervasive red dust, and cyclone-prone weather patterns without operational disruptions. The system supports continuous, remotely monitored drone flights with automatic recharging, enhancing both safety and productivity. This endurance not only safeguards the equipment investment but also facilitates seamless data acquisition critical for timely decision-making and compliance. DJI Dock Mining Automation’s focus on operational reliability in harsh conditions empowers mining companies to adopt automated drone workflows confidently.

Planning, Scheduling, and On-Demand Drone Flights

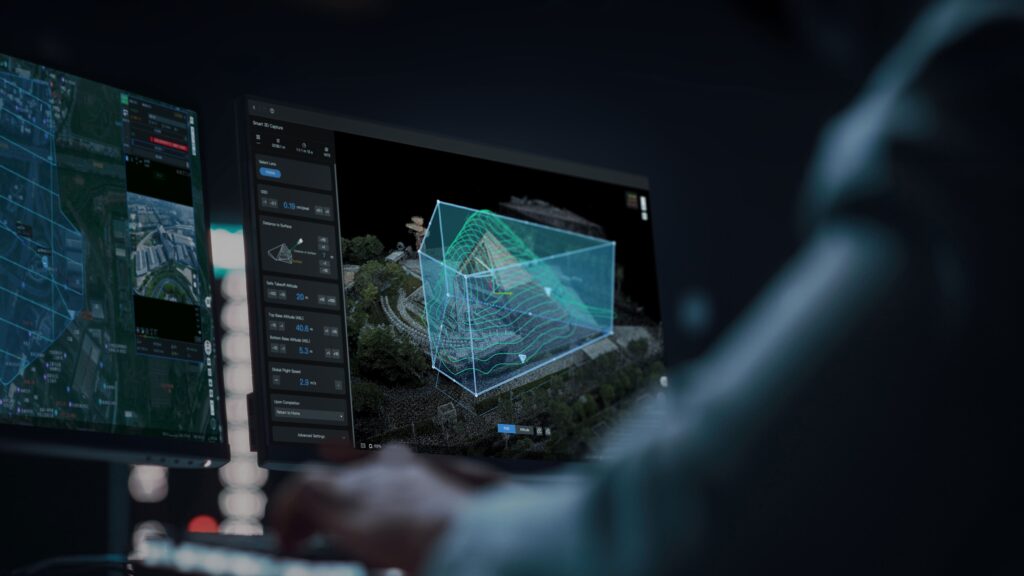

DJI Dock Mining Automation empowers mining operations with advanced planning, scheduling, and on-demand flight capabilities that optimize aerial workflows while minimizing human intervention. This automated approach allows operators to remotely schedule missions in advance, program precise flight paths, and deploy docked drones when immediate data capture is needed. Such flexibility enables round-the-clock aerial monitoring of mining sites, ensuring critical inspections and surveys are conducted regularly and efficiently without requiring onsite pilots. Combined with seamless integration into DJI FlightHub 2, this system offers centralized flight management, real-time monitoring, and data synchronization for enhanced operational control.

Remote Mission Planning and Scheduling

Operators can pre-plan drone missions from a central control room using intuitive software interfaces. With DJI Dock Mining Automation, flights can be accurately scheduled around operational needs, weather windows, or regulatory constraints, ensuring comprehensive coverage without manual dispatch at the site.On-Demand Flight Activation

When unplanned aerial perspectives are required, docked drones can be piloted remotely instantly. This capability supports reactive inspections, emergency response, and verification tasks, delivering timely data precisely when decisions need to be made.Automated Takeoff, Landing, and Charging

Drones autonomously launch from and return to the dock, where automated charging systems prepare them quickly for subsequent missions. This cycle reduces downtime and maximizes flight frequency, enabling continuous site oversight.Flight Path Customization and Adjustments

Mission routes can be created, edited, or refined dynamically based on incoming data, ensuring evolving site conditions or priorities are addressed without significant operational disruption.Centralized Fleet and Data Management

All flight operations, including scheduling and live telemetry, integrate into DJI’s FlightHub 2 platform for cohesive oversight. Collected data uploads automatically, enabling streamlined processing, analysis, and reporting workflows vital for mining efficiency and compliance.

Conclusion

DJI Dock Mining Automation represents a transformative leap forward in mining technology by seamlessly integrating automated drone workflows with remote management capabilities. This innovative solution allows mining operations to increase efficiency, enhance safety, and deliver precise, real-time data without placing personnel in hazardous environments. By enabling frequent, scheduled, and on-demand drone flights, DJI Dock Mining Automation not only accelerates data collection and processing but also enhances decision-making and operational agility in challenging conditions.

The reliability and robustness of DJI Dock Mining Automation have been proven through real-world deployments in extreme environments, ensuring continuous operations even in intense heat, dust, and adverse weather. As the mining industry continues to evolve, embracing this automated drone technology offers significant productivity gains, cost savings, and improved compliance. Ultimately, DJI Dock Mining Automation stands as a future-ready platform that empowers mining enterprises to meet today’s operational demands while paving the way for more sustainable and efficient mining workflows tomorrow.