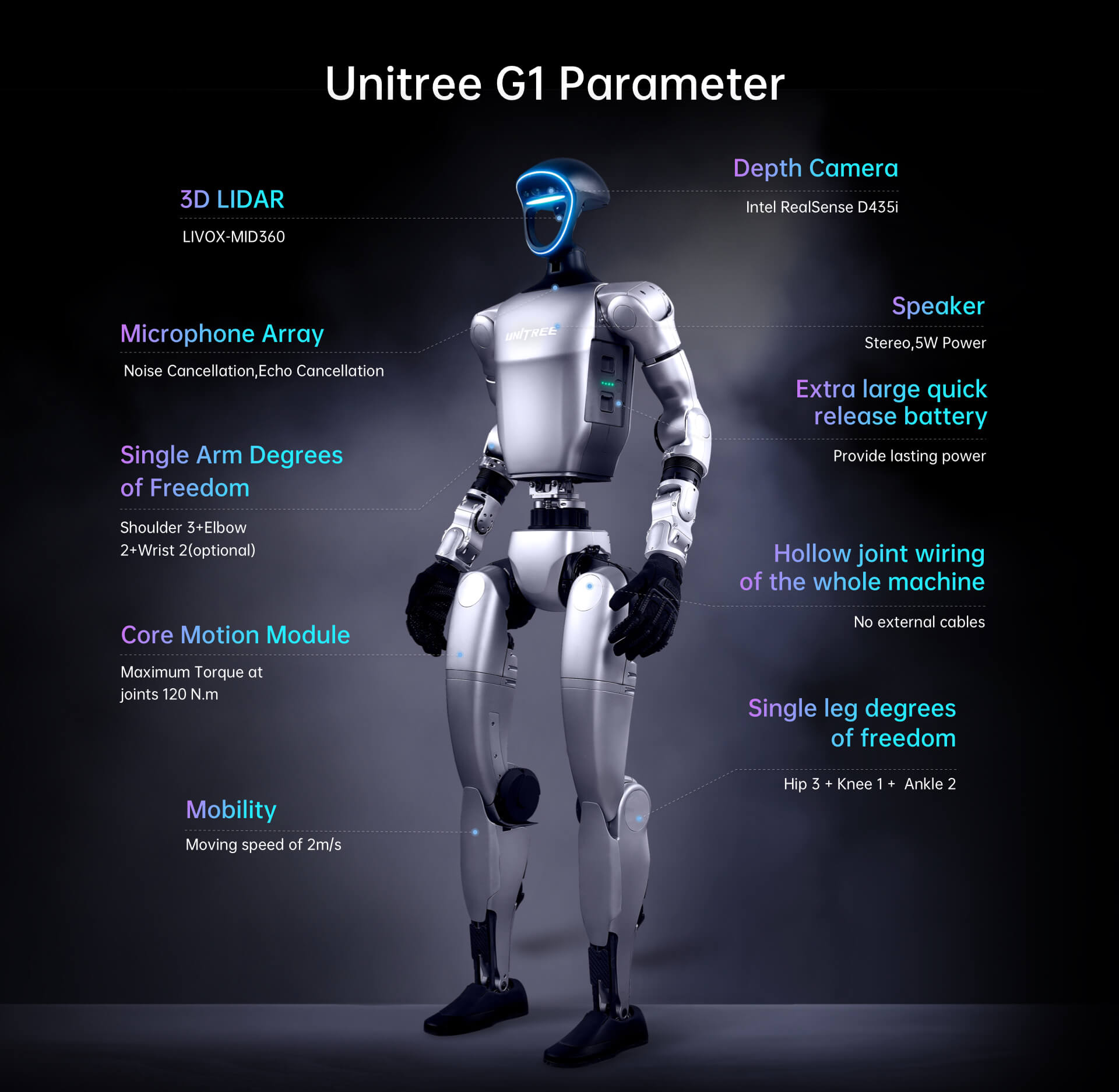

Introducing the Unitree G1 – Humanoid Robot

Introducing the Unitree G1 – Humanoid Robot, a revolutionary platform that blends advanced artificial intelligence with precision-engineered robotics. Designed for ultimate flexibility, the G1 features a configurable motion system with 23 to 43 motors, allowing it to perform smooth, human-like movements and navigate complex environments with exceptional agility. What sets the G1 apart is its force-control dexterous robotic hand, capable of replicating human-like manipulation with high sensitivity and reliability—making it ideal for delicate tasks in research labs or industrial settings. At its core, the G1 is powered by Unitree’s proprietary UnifoLM (Unified Large Model) technology, enabling intelligent learning, collaborative interaction, and real-time adaptation. This makes it a powerful tool for applications in education, R&D, and commercial robotics. Fully modular and customizable, the Unitree G1 can be tailored to meet specific project needs across multiple industries. For detailed specifications, pricing, and delivery options, please contact our sales team for personalized assistance.

Real-World Applications of the Unitree G1 Humanoid Robot

The Unitree G1 Humanoid Robot is transforming real-world applications with advanced AI, agile mobility, and human-like precision. From robotics research and STEM education to industrial automation and smart surveillance, the G1 delivers cutting-edge performance across diverse sectors. Its adaptive joint motion, force-controlled hands, and customizable design make it ideal for tasks such as object manipulation, environment interaction, and collaborative robotics. Whether in labs, factories, or public environments, the Unitree G1 stands out as a powerful humanoid robot built for innovation and real-world deployment.

1.Industrial Automation:Automates repetitive and complex tasks in manufacturing, logistics, and smart factories to boost speed and precision.

2.AI-Powered Precision:Performs object detection, sorting, and manipulation with high accuracy using advanced artificial intelligence systems.

3.Workplace Safety:Reduces human risk by operating in hazardous environments like construction sites, disaster zones, and industrial plants.

4.Robotics in Healthcare:Assists with patient interaction, elder care, and rehabilitation support, enhancing efficiency and safety in medical settings.

5.STEM Education & Research:Used by universities and research labs for hands-on learning in robotics, AI, mechatronics, and control systems.

6.Customizable Design:Features modular hardware and open software architecture, allowing adaptation for various industry-specific needs.

7.Human-Robot Collaboration:Designed to work safely alongside humans in collaborative tasks within factories, warehouses, and service industries.

8.Mobility & Dexterity:With up to 43 actuated joints and force-sensitive hands, it navigates and interacts with complex environments fluidly.

Functions of G1

the Unitree G1 features 23–43 joint motors enabling ultra-wide movement angles and lifelike agility

Witness the precision and power of the Unitree G1 humanoid robot in action – engineered for robotics innovation and real-world deployment

The Unitree G1 humanoid robot in action – showcasing advanced mobility, intelligent control, and real-world application potential

Watch the Unitree G1 humanoid robot demonstrate real-world agility, precise motion, and intelligent robotics engineering

Add Your Heading Text Here

Specifications

Mechanical Specification

| Specification | G1 | G1 EDU |

|---|---|---|

| Height, Width, Thickness (Stand) | 1320×450×200mm | 1320×450×200mm |

| Height, Width, Thickness (Fold) | 690×450×300mm | 690×450×300mm |

| Weight (with Battery) | About 35kg | About 35kg+ |

| Total Degrees of Freedom (DOF) | 23 | 23–43 |

| Single Leg DOF | 6 | 6 |

| Waist DOF | 1 | 1 + (Optional 2 additional waist DOF) |

| Single Arm DOF | 5 | 5 |

| Single Hand DOF | / | 7 (Force control, 3-fingered) + 2 (Optional wrist DOF)Dex3-1 with 3-finger: Thumb (3 DOF), Index (2 DOF), Middle (2 DOF); Optional tactile sensors |

| Joint Output Bearing | Industrial-grade crossed roller bearings | Industrial-grade crossed roller bearings |

| Joint Motor | Low inertia PMSM (better speed & heat dissipation) | Low inertia PMSM (better speed & heat dissipation) |

| Max Knee Joint Torque | 90 N·m | 120 N·m |

| Arm Max Load | ~2 Kg | ~3 Kg |

| Calf + Thigh Length | 0.6 m | 0.6 m |

| Arm Span | About 0.45 m | About 0.45 m |

| Joint Movement Range | Waist: Z ±155°Knee: 0–165°Hip: P ±154°, R -30°~+170°, Y ±158° | Waist: Z ±155°, X ±45°, Y ±30°Knee: 0–165°Hip: P ±154°, R -30°~+170°, Y ±158°Shoulder: P ±92.5°, Y ±92.5° |

Electrical Specification

| Specification | G1 | G1 EDU |

|---|---|---|

| Full Joint Hollow Electrical Routing | YES | YES |

| Joint Encoder | Dual encoder | Dual encoder |

| Cooling System | Local air cooling | Local air cooling |

| Power Supply | 13-string lithium battery | 13-string lithium battery |

| Basic Computing Power | 8-core high-performance CPU | 8-core high-performance CPU |

| Sensing Sensor | Depth Camera + 3D LiDAR | Depth Camera + 3D LiDAR |

| 4 Microphone Array | YES | YES |

| 5W Speaker | YES | YES |

| WiFi 6 + Bluetooth 5.2 | YES | YES |

Accessories

| Specification | G1 | G1 EDU |

|---|---|---|

| High Computing Power Module | / | NVIDIA Jetson Orin |

| Smart Battery (Quick Release) | 9000mAh | 9000mAh |

| Charger | 54V 5A | 54V 5A |

| Manual Controller | YES | YES |

| Battery Life | About 2 hours | About 2 hours |

| Upgraded Intelligent OTA | YES | YES |

| Secondary Development [3] | / | YES |

FAQs

How does the AI-driven imitation and reinforcement learning system in the G1 enhance its task efficiency?

The G1 employs AI-powered imitation learning to replicate human movements and reinforcement learning to improve its decision-making over time. This system allows it to adapt to various environments, making it capable of handling complex tasks with greater efficiency and accuracy than traditional programming alone

What specific force control techniques are utilized in the G1’s dexterous hand, and how do they impact its manipulation capabilities?

The G1’s hand integrates force-position hybrid control, which allows it to adjust its grip strength based on the feedback from the object it’s handling. This enables delicate manipulation, similar to human touch, making it suitable for tasks like assembling small parts or handling fragile items in healthcare

How does the G1’s dual encoder system contribute to its motion accuracy and stability?

The dual encoder provides precise feedback for each joint’s position, enhancing accuracy in movement and stability under dynamic conditions. This system helps maintain balance and control, which is crucial for tasks that require consistent force and coordination, especially in unpredictable environments

What challenges might arise in programming the G1 for custom tasks, given its high degrees of freedom?

With 23–43 degrees of freedom, the G1’s complexity can make custom programming challenging. Developers need to manage each joint and actuator, which requires sophisticated algorithms for coordinated movement, especially in tasks involving multiple simultaneous actions

How does the G1’s design mitigate potential issues of overheating during prolonged operation?

The G1 includes a local air-cooling system, which helps maintain optimal operating temperatures. This system prevents overheating during continuous usage, such as in research labs or during long inspection tasks in hazardous environments

What are the limitations of the G1’s 3D LiDAR and depth camera in navigation and object detection?

While 3D LiDAR and depth cameras provide spatial awareness and obstacle detection, their effectiveness can be limited by environmental factors like low lighting or reflective surfaces, which may cause inaccurate readings. The G1 may require additional sensor data for tasks in highly variable or cluttered environments

In what ways can secondary development enhance the G1’s performance in specialized applications?

Secondary development allows users to write custom code, tailoring the G1’s performance to specific needs, such as custom locomotion patterns or sensor integration for industry-specific tasks. This flexibility makes it highly adaptable, though advanced programming knowledge is essential for effective customization

What safety measures are in place to prevent damage or malfunction in hazardous or unpredictable environments?

The G1 is equipped with collision detection and force control, which help it avoid obstacles and regulate the strength of its movements to prevent damage. Additionally, remote control capabilities allow human operators to override actions in emergency situations

Reviews

There are no reviews yet.